Welcome to Wenzhou Yiran Import & Export Co., Ltd.

Product

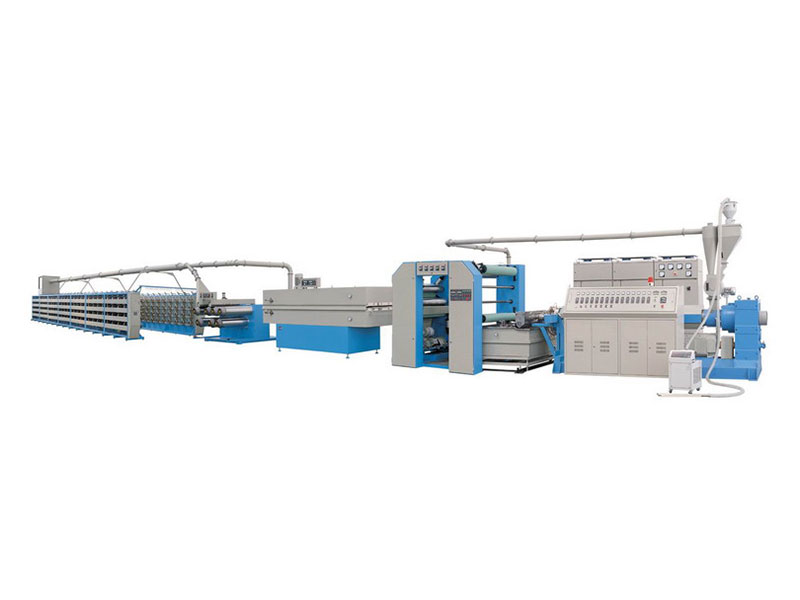

High-speed flat yarn production line

Performance and Characteristics

High-speed flat yarn extrusion line is designed and developed on the base of introducing and assimilating the up-to-date technologies at home and abroad. It adopts the international electric digital-simulation control technology such as computer-controlled frequency conversion speed regulation so as to make the main target reach the international advanced level. Meanwhile, with high production efficiency and high quality of tape tube forming, as required, this assembly can also be equipped with advanced filter change structure as well as fibrosis structure that is used for producing flexible packaging bags or fibrillated sewing thread.

This line has two kinds of stock thread heating structures, i.e. hot-blast stretching oven and electric baking board for customers’ alternatives. Applied to a wide range, it can be used for the forming of PP, HDPE and LLDPE flat yarn.

Main technical parameters

| Model | PL-SPL-80/33/800 | PL-SPL-90/33/1000 | PL-SPL-110/30/1200 | PL-SPL-120/30/1500 |

| Max. Output (kg/h) | 200 | 280 | 380 | 500 |

| Dia. of screw (mm) | 80 | 90 | 110 | 135 |

| Speed of screw (r/min) | 20-120 | 20-120 | 20-120 | 20-120 |

| Ratio of screw | 33:1 | 33:1 | 30:1 | 30:1 |

| Width of die (mm) | 800 | 1000 | 1200 | 1500 |

| Max. liner speed (m/min) | 280 | 280 | 280 | 280 |

| Denier scope (tex) | 60-200 | 60-200 | 60-200 | 60-200 |

| Drawing ratio | 4-10 | 4-10 | 4-10 | 4-10 |

| Spindles of winder | 136 | 176 | 208 | 256 |

| Size of bobbin (D×L) (mm) | 38×230 | 38×230 | 38×230 | 38×230 |

| Power (Kw) | 240 | 290 | 320 | 380 |

|

Installing dimension (L×W×H) (mm) |

13300×1500×2000 | 14700×1750×2000 | 16500×2050×2000 | 17200×2600×2200 |

| Weight (kg) | 21000 | 26000 | 30000 | 32000 |