Welcome to Wenzhou Yiran Import & Export Co., Ltd.

Product

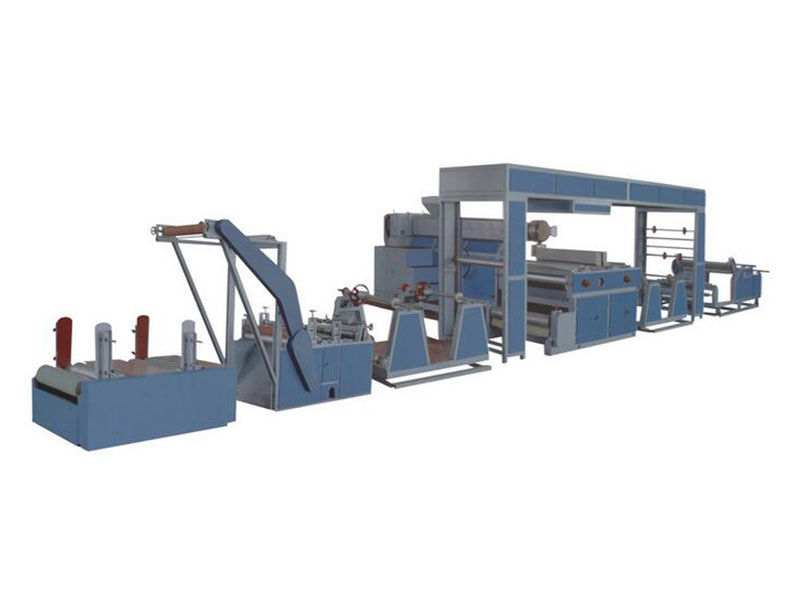

Multifunctional lamination machine

Performance and Characteristics

Making use of the good adhesive property of polypropylene & polyethylene at melting status, the machine adheres and laminates paper or color-printed OPP

& CPP film to woven bag under pressure, and through cutting-off and sewing to make paper & plastic laminated or color-printed packaging woven bags. It can do coating on woven bags with melted polypropylene & polyethylene film to make laminated woven bag.

The extruder, with helical gear reducer of 20CrMnTi alloy steel and the screw & cylinder made of nitrided 38CrMoAlA alloy steel adopts automatic temperature control system to adjust melting temperature. Width of coating & laminating can be regulated, and step-less speed regulation is to control coating thickness and laminating speed, 6 stations for material feeding. The pneumatic-hydraulic edge correction for rewinder assures the accuracy of coating. Pneumatic roller can assure even pressure. Edge-blowing, edge-correction and winding devices are applied.

Main technical parameters

| Model | Dia. of screw (mm) |

L/D ratio of screw |

No. of die |

Width of die | Gross power (Kw) | Motor power of extruder (Kw) | Max. coating width (mm) | Speed (m/min) |

Installing dimension (L×W×H) (mm) |

Weight (kg) |

| PL-FHJ-1000 | 90 | 28:1 | 2 | 1000 | 71 | 15 | 750 | 50-120 | 14000×6000×3000 | 8000 |